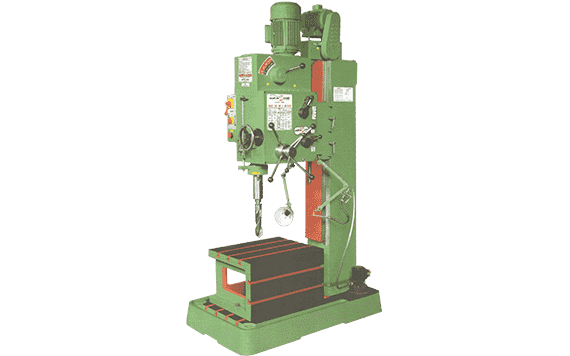

Key Features

-

Main spindle is made of "EN9" material & Hardness.

-

MT-bore-internally grinded.

-

Accurancy and run out of 0.01 to 0.03 is main spindle shafts.

-

Pinion Shafts is made of "EN8" material and hardness.

-

Provided 4-8 Speeds by accurate balancing.

-

Spindle Sleeve-grinded.

-

By simple adjustment of only wedge facility to set drill head on column guide way.

-

Work light [As per requirement]

-

Box work table [As per requirement]

-

Auto feed [4/0.10 To 0.25mm]

-

Coolant system [As per Requirement]

-

Adjustable depth control [with auto stop]

-

Nitride hardened "RAM"

-

All gears are made of alloy steel [Gear Material] Heat treatment [50 to 60 HRC] hardened & Lapped running in oil bath fitted with splined shafts.

-

Ram is accurately grinded and honing process is done in the bore body containing ram.

-

All the gears assemble in the machine in the are perfectly sized according to requirement [Precision gears]

-

All Bearing [SKF & NBC Bearing]

-

All Electrical parts are good quality.[Company : L&T]

-

Pinion and worm is grinded as per the sizes required

-

Square column guide surface R precision scraping process

-

Precision ground alloy gears

-

Spindle reverse and tapping control (as per required)

-

Specially spring type balanced spindle travel

-

Emergency stop button

-

Auto/Manual feed options

-

Drilling last Capacity.:50mm

-

Heavy Duty structures

-

Strongly ribbed and thick walled base plate having built-in coolant tank. arm for maximum rigidity and minimum deflection

-

Size of T-slots : 4/200MM.Wooden case available on demand.

-

No.1 Suppliers Worldwide

-

Certified ISO 9001:2008

-

Leading Service Provider